Introduction:

Gearboxes are essential components in various mechanical systems for transmitting high power. They facilitate the transfer of torque from a prime mover to a load by altering the speed and direction of the input power. In this blog post, we will explore the different types of gearboxes, their applications, and their benefits.

Types of Gearboxes:

Parallel Shaft Gearbox:

A simple and commonly used gearbox that transmits power between parallel shafts. It consists of two parallel shafts supported by bearings and connected by a set of gears with straight teeth. The input shaft drives the pinion gear, which meshes with the larger gear on the output shaft, transferring torque and rotational speed from the input to the output shaft. Parallel shaft gearboxes are suitable for low-speed, high-torque applications such as conveyors, cranes, and hoists. Their applications include various industrial machinery, marine, and automotive applications. However, they can produce significant noise and vibration due to the straight-cut gears and necessitate regular lubrication for proper operation and extended service life.

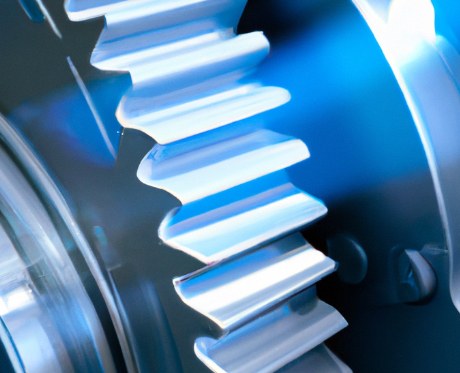

Helical Gearbox:

An advanced version of the parallel shaft gearbox featuring angled teeth for smoother operation and reduced noise. It is suitable for high-speed and high-torque applications such as machine tools and printing presses.

Bevel Gearbox:

A gearbox that transmits power between intersecting shafts at an angle, enabling a change in the direction of power transmission. It is helpful in various applications such as marine propulsion, differential drives, and right-angle drives.

Worm Gearbox:

this gearbox employs a worm and wheel to transfer power between perpendicular shafts. It is ideal for high-torque and low-speed applications such as elevators, conveyors, and winches.

Planetary Gearbox:

A complex gearbox that utilizes multiple planetary gears for power transmission. Offering high power density, compact size, and precise motion control, it is ideal for robotics, aerospace, and automotive applications.

Benefits of Gearboxes:

- Torque multiplication: Gearboxes allow for torque multiplication, enabling high-power transmission in various mechanical systems.

- Speed reduction/increase: Gearboxes can alter power transmission speed, facilitating the efficient operation of machines and equipment.

- Directional change: Gearboxes can change the direction of power transmission, allowing for efficient power transfer between different mechanical components.

- Noise reduction: Advanced gearboxes, such as helical and planetary, operate with reduced noise levels, making them ideal for noise-sensitive applications.

- Compact design: Some planetary gearboxes are compact, enabling high-power transmission in tight spaces.