Are you in search of top-tier equipment solutions for the sugar industry?

Look no further! We supply a comprehensive range of equipment designed to enhance efficiency, productivity, and sustainability in sugar processing.

Our offerings include:

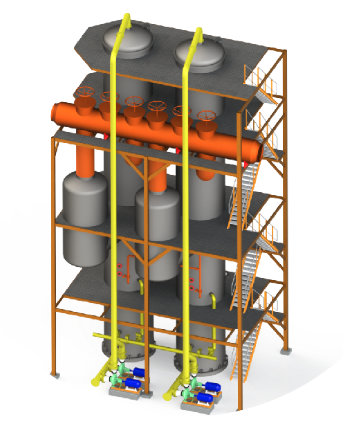

Shell and Tube Heat Exchangers

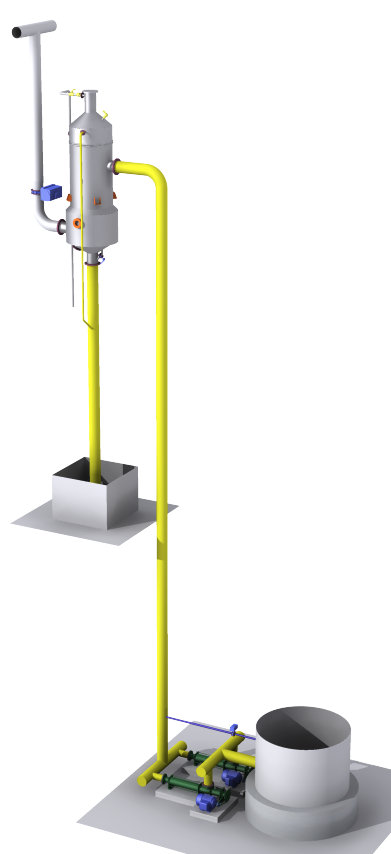

Direct Contact Heaters

Syrup Clarifier System

Falling Film Evaporator

Seed Preparation Mill Equipment for Boiling Operation in a Sugar Cane Factory

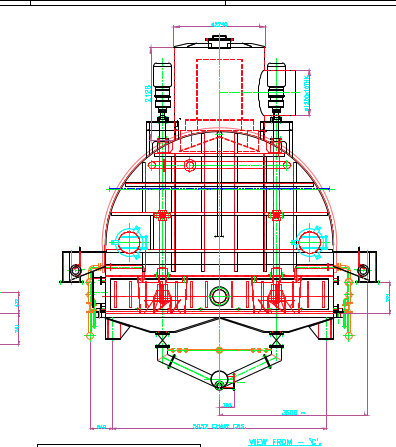

Continuous Vacuum Pan – Horizontal Unique Design & Capabilities

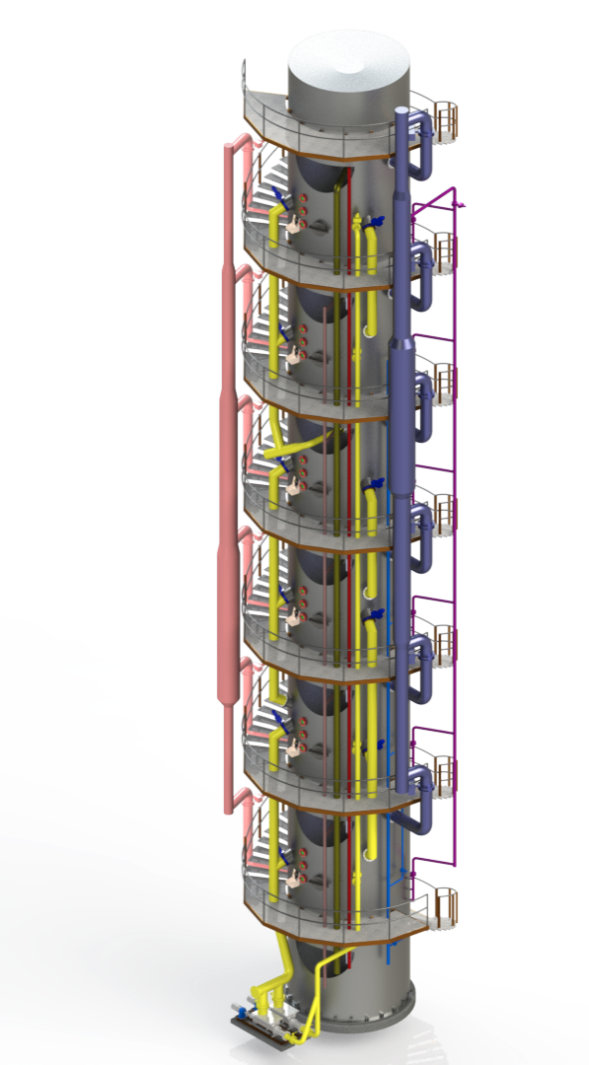

Vertical Vacuum Pan Solutions

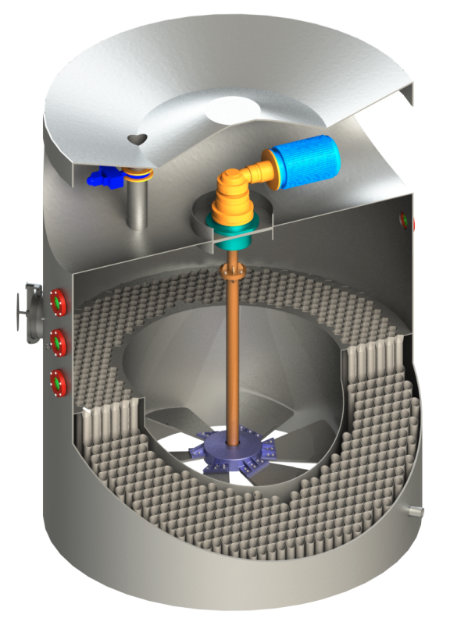

Batch Vacuum Pan Circulators

Horizontal Crystallizers

Vertical Cooling Crystallizer

Molasses Conditioner

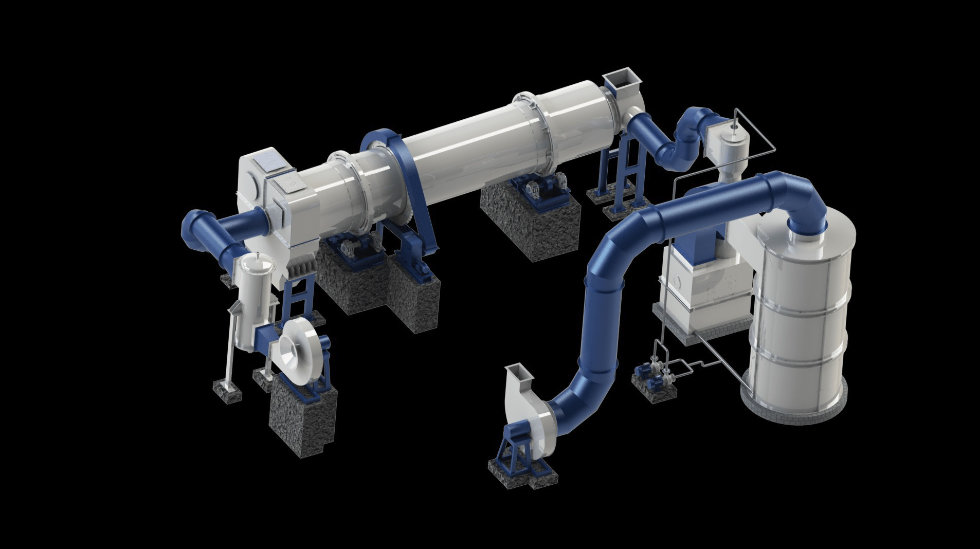

Rotary Sugar Dryer

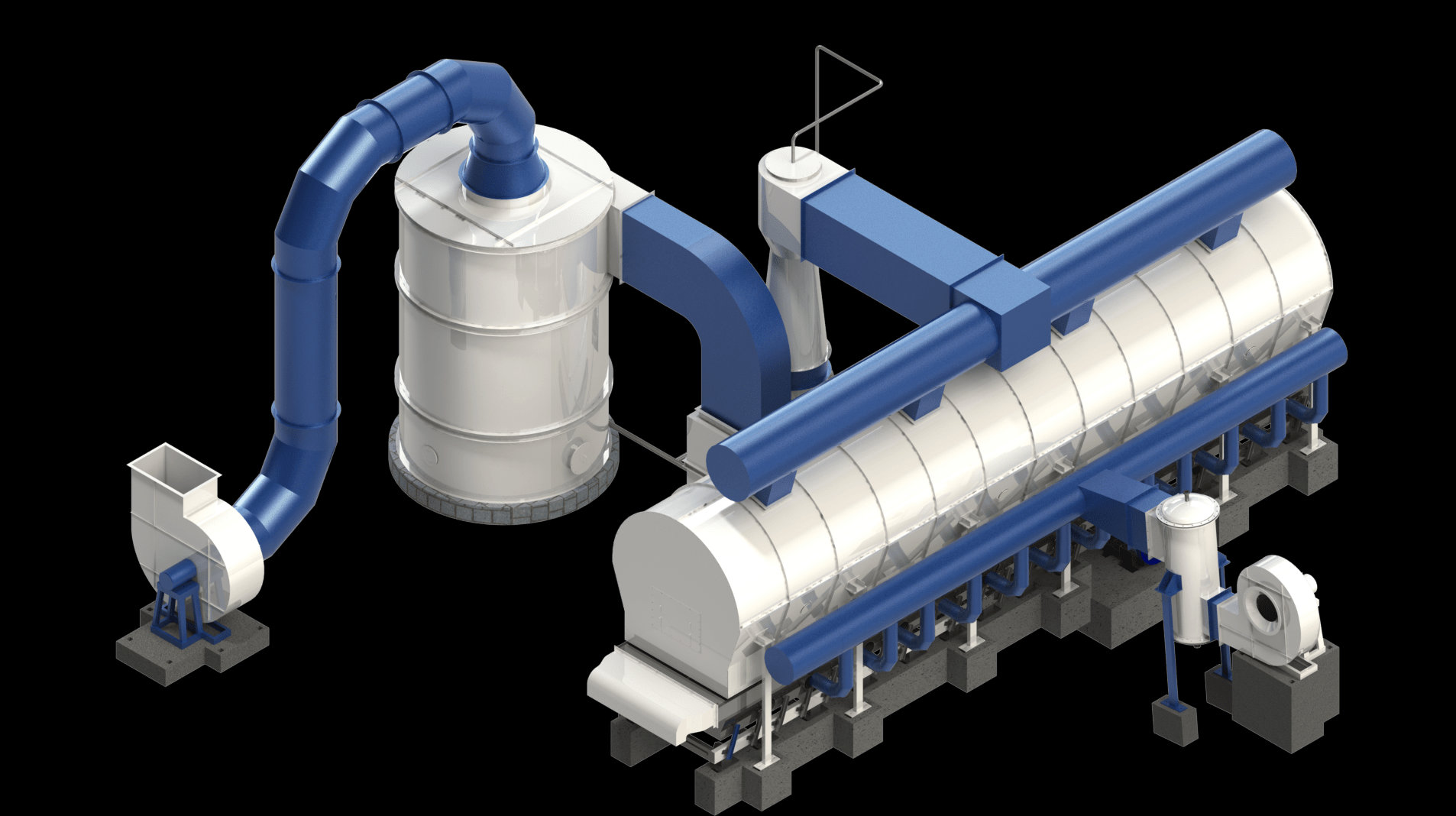

Fluidized Bed Dryer (FBD)

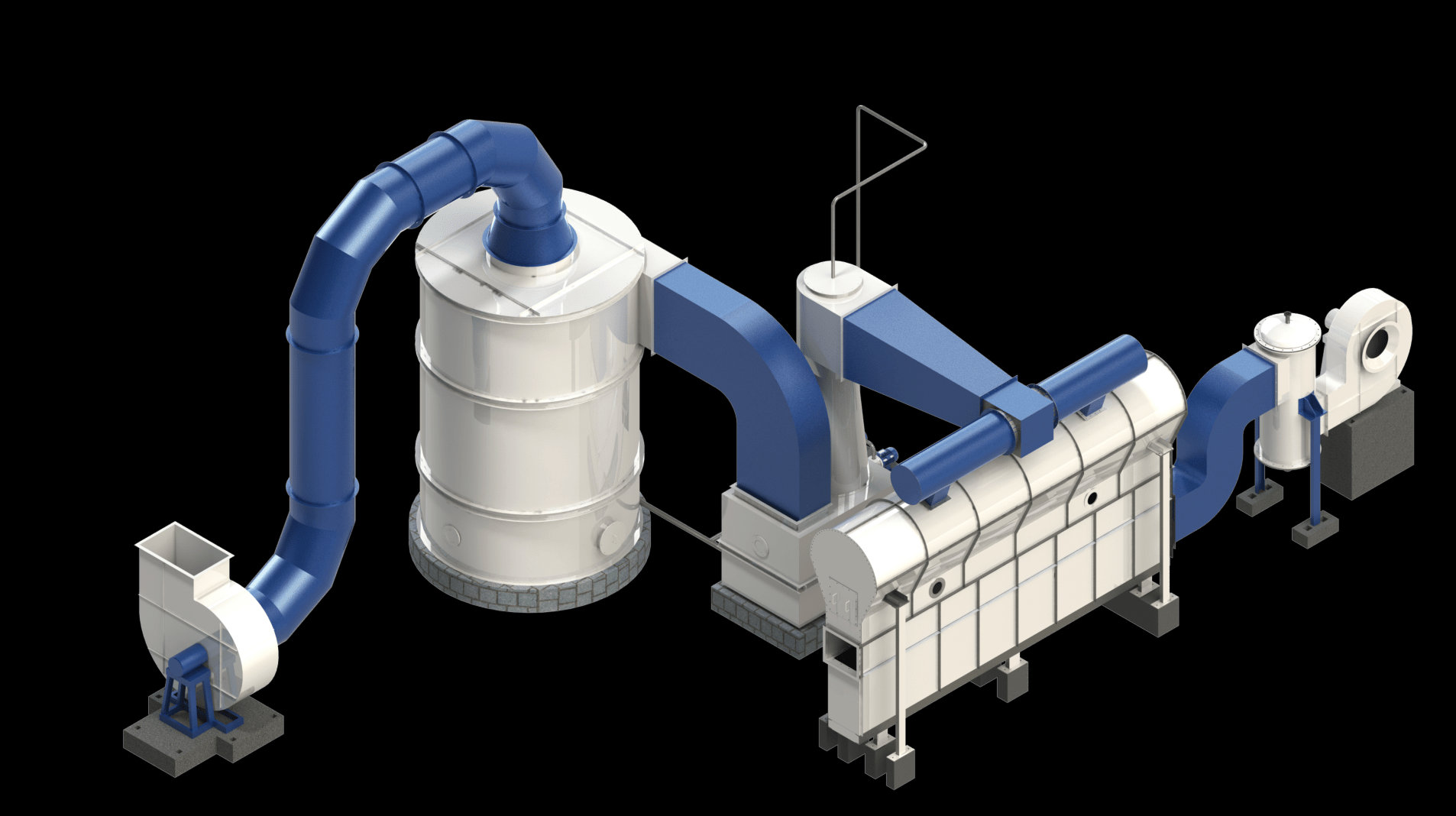

Static Fluidized Bed Sugar Dryer

Our commitment to quality, innovation, and customization sets us apart as a trusted partner in the sugar industry. To learn more about our equipment, explore tailored solutions, and discuss how we can meet your specific requirements, please don’t hesitate to reach out.Email us at sugar@crompion.com , and our team of experts will be delighted to provide you with all the information you need to take your sugar processing operations to the next level.

Discover the future of sugar industry equipment with us. Contact us today!