In today’s rapidly evolving industrial landscape, the need for efficient, reliable, and innovative solutions is more critical than ever. One such innovation that has been making waves in the field of industrial couplings is Crompion’s Split Elastic Coupling. We will explore how this cutting-edge technology is helping industries worldwide optimize their operations for enhanced productivity and reduced downtime.

Traditional couplings have been the backbone of machinery for decades, providing the essential link between two rotating shafts. However, as industries grow more demanding, the limitations of these couplings become increasingly apparent. The Split Elastic Coupling from Crompion is designed to address these limitations head-on.

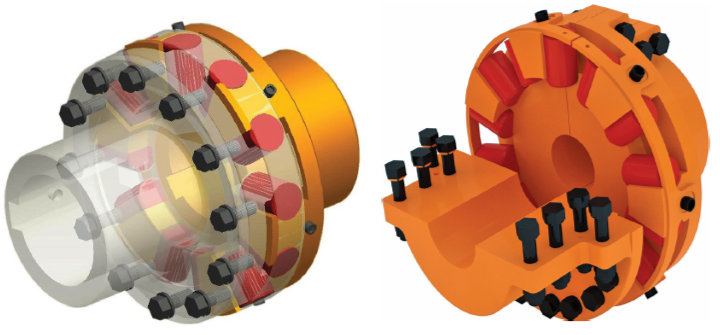

The Split Elastic Coupling boasts a range of features that set it apart from conventional couplings:

- Split Design: One of the most innovative aspects of Crompions’s Split Elastic Coupling is its split design. This means that installation and maintenance are incredibly straightforward, reducing downtime and labor costs. No need to disassemble the entire system for coupling replacement or maintenance.

- High Torsional Flexibility: Crompions’s Split Elastic Coupling offers exceptional torsional flexibility, allowing it to accommodate misalignments and shock loads. This not only protects your machinery but also extends its operational life.

- Enhanced Torque Transmission: With a high torque capacity, Crompions’s Split Elastic Coupling ensures reliable power transmission even in the most demanding industrial environments.

- Vibration Dampening: The coupling effectively dampens vibrations, reducing wear and tear on connected equipment and enhancing overall system stability.

- Easy Inspection: Its split design also makes inspection and maintenance a breeze. Visual inspection is possible without the need for complete disassembly, saving time and effort.

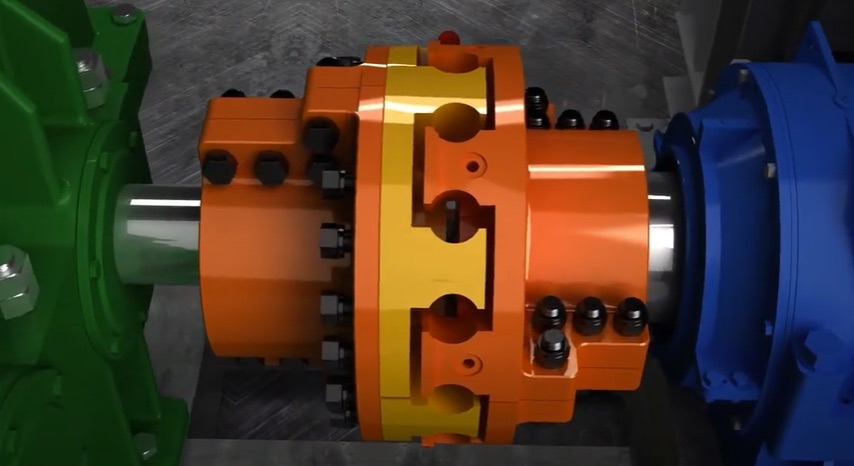

Crompions’s Split Elastic Coupling finds applications in various industries, including the sugar industry, manufacturing, mining, energy, and more. It excels in systems with high torque and variable operating conditions, making it a versatile choice for modern industrial setups.

To cater to various applications and project needs, Crompion offers Couplings in multiple sizes, accommodating shaft diameters ranging from 25 to 600mm. They boast impressive load capacities of up to 1.417.600 Nm.

Crompions’s Split Elastic Coupling are designed with interchangeability in mind. Five different constructive forms with interchangeable elements are available, offering flexibility in meeting specific project requirements.

In a world where efficiency and reliability are paramount, Crompion’s Split Elastic Coupling stands out as a game-changer. Its innovative design, high torque capacity, and ease of maintenance make it an ideal choice for industries striving to optimize their operations.

As technology continues to advance, solutions like Crompions’s Split Elastic Coupling enable industries to keep pace with ever-increasing demands. To learn more about this remarkable coupling and how it can benefit your sugar industry, visit Crompions’s coupling product page.

Investing in the right coupling technology is an investment in the future of your industrial processes. Crompions’s Split Elastic Coupling is undoubtedly a step in the right direction.