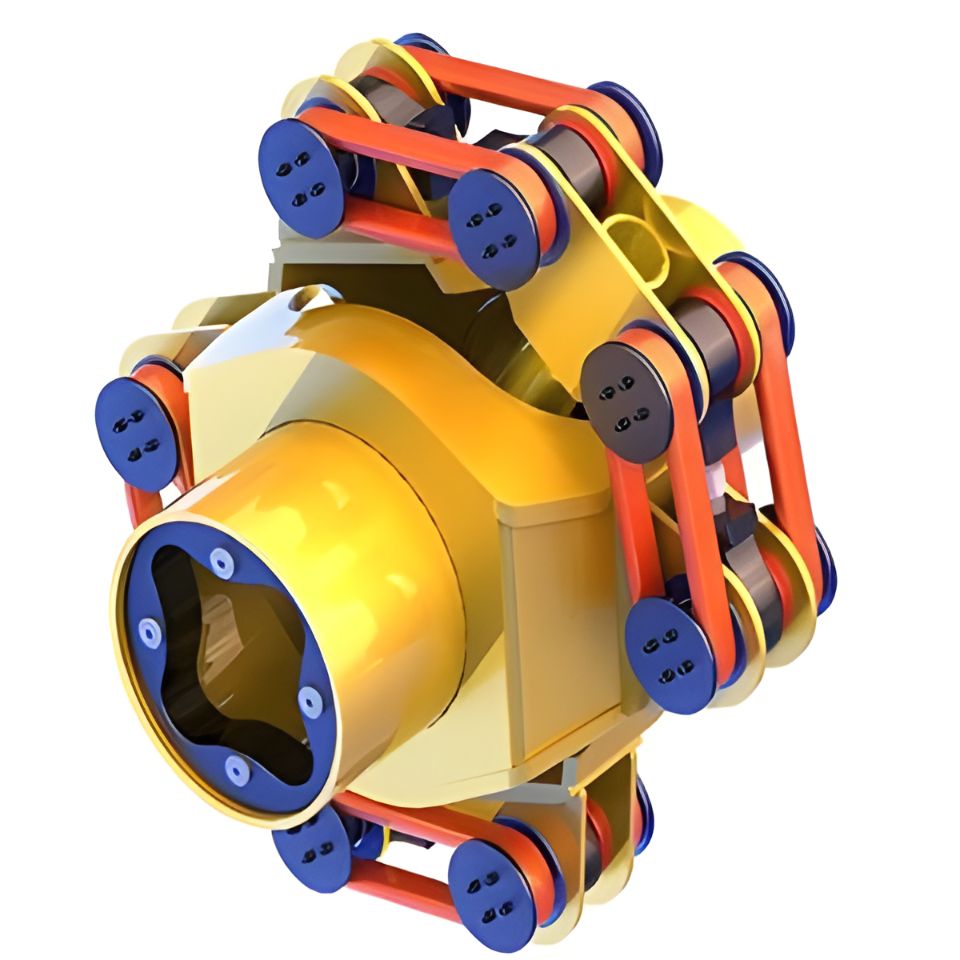

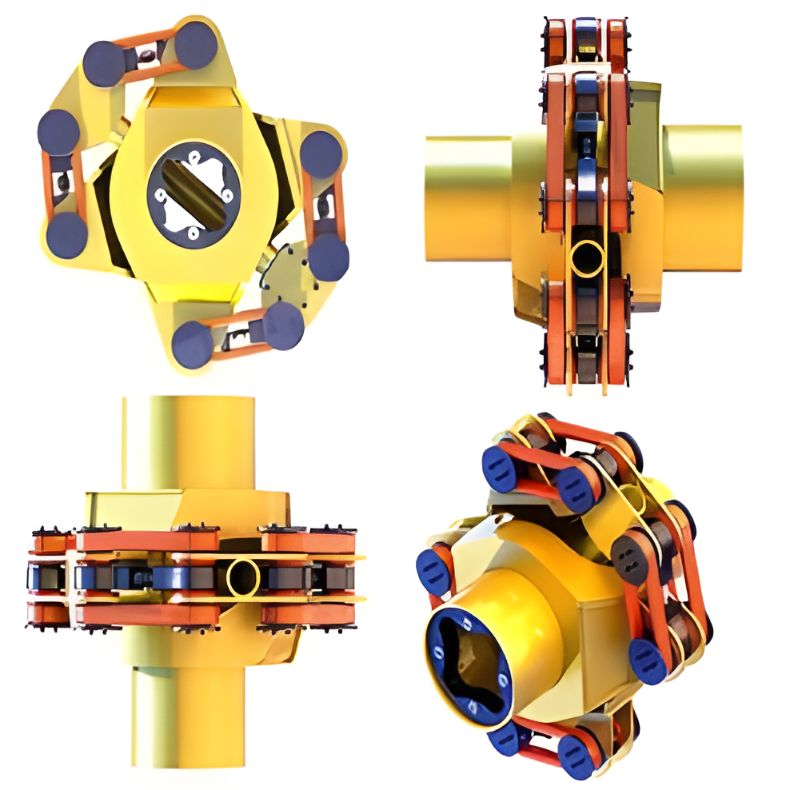

Welcome to the future of mill operations! Crompion is proud to present the revolutionary Multi Mis-Alignment Rope Coupling (MMRC), a game-changer in the transmission of torques from gear to mill top. Bid farewell to outdated square couplings and tail bars, and embrace a design that offers unparalleled flexibility, efficiency, and minimal maintenance.

Key Features:

- Flexible Design with Polyester Slings: The MMRC employs Polyester Slings to achieve a design that is remarkably flexible, capable of absorbing substantial mis-alignments between the top roller and the output shaft of the driving gear.

- Balanced Couples for Minimal Strain: The MMRC creates balanced couples in a plane normal to the coupling axis, eliminating the bending moments and thrust typically generated by mis-alignments between gear and top roller.

- Enhanced Extraction Performance: Unlike traditional tail bars, the MMRC allows unrestricted movement of the Mill Top Roller, contributing to improved mill efficiency and performance.

- Lower Final Bagasse Moisture: When installed on the last mill, the MMRC is designed to contribute to lower final bagasse moisture, ensuring optimal results.

- Mis-Alignment Absorption: The MMRC excels in absorbing mis-alignments between the square end of the gear shaft and the top roller, mitigating lateral thrust and bending moments.

- Reduced Torque and Power Consumption: A boon for environmental and economic concerns, the MMRC significantly reduces torque and power consumption.

- Breakage Elimination: Say goodbye to the risk of crown pinion and top roller breakage, as the MMRC provides a robust and durable solution.

- Negligible Maintenance: In the pursuit of operational efficiency, the MMRC demands minimal maintenance, ensuring a hassle-free experience for mill operators.